Problem Analysis Methods for Manufacturing Sites (Use of FTA)

In this article, I will be talking about the theme of 'Problem Analysis Methods for Manufacturing Sites (Use of FTA)'. Most people think of it as little more than a "solution to quality problem". However, this is wrong for its original purpose. I'll explain why on this page.

FTA is problem analysis method

FTA, which stands for Fault Tree Analysis, is a problem analysis technique commonly used in the manufacturing industry.

Anyone who works in the manufacturing industry will be familiar with this information.

Sometimes we make a proper FTA when we raise a quality issue with customer, but I have the impression that few people use it in their daily work, for example, for defect analysis.

Everyone should have "knowledge" of it.

Unfortunately, few people seem to be able to "practice" it.

This is a very useful problem analysis method for working in production engineering, so try it out when you are faced with complex problem.

How to do FTA and case study of problem analysis

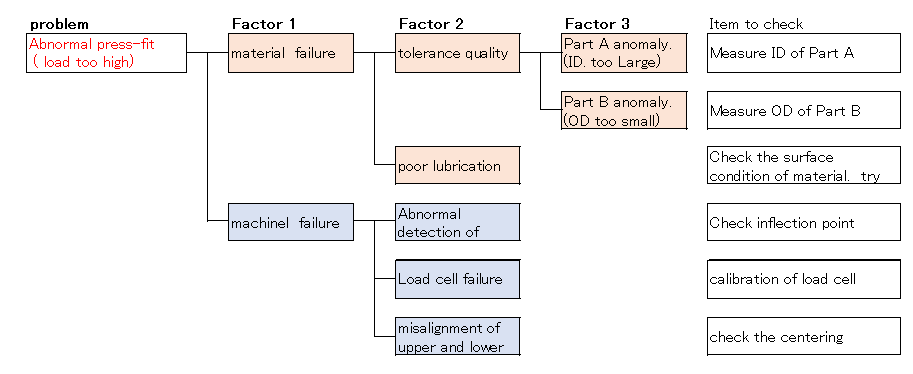

To give a simple example, suppose that a problem called "press fit abnormality" occurs during the press fitting process of two parts. A major classification is made as follows

- Material factors (inadequate dimensions of the press-fit part, coaxiality of the press-fit or positioning part, etc.)

- Equipment factors (e.g., parameters, fixture anomalies, etc.)

- Others (rust due to storage conditions of material, changes in surface oils and grease, etc.)

The method is to write down the factors that led to the branches for each item and then check and verify each item to find the true cause.

For example, in the case of abnormal press fit, you can divide the situation into material and equipment factors as follows.

Then write down the related factors from the left side.

*In the case of talented person, the items and relationships are well organized, making the next task easier.

When you have finished writing, you can list the items to be checked on the right side.

The rest of the process involves going through these checklist items one by one to find the true cause of the problem.

It's easy to say, but it's hard to actually do. In my experience, the better engineers use this technique. Incapable people will only state their assumptions without verification.

Characteristics of talented person

The talented people do this analysis in their minds. If the problem is complicated, there is more verification work to be done, so they will create an FTA to organize the information once they have verified some of it.

Characteristics of typical engineer

Those who aren't good at it are not able to do the validation work or organize the results. This is not the way to solve the problem.

At the time, I was in a position to lead others, so I was telling people who couldn't solve their issues to create FTAs.

I didn't want them to just create an FTA, but I wanted them to practice the idea of problem-solving.

However, the more people who would need to create such an FTA, the less likely they are to create it, surprisingly.

In the end, the problem is not clear in their own mind.

The advantages of using the FTA to analyze the problem

The FTA can help you organize your issues. It is applicable to a variety of internal problems, not just quality issues, and not just for production engineering jobs.

For example, you can adapt to any challenge, whether it's an employee training problem, a talent shortage problem, marketing problem, or cash flow problem.

This is a major advantage of the FTA approach. You don't adopt it because someone told you to, but because it's useful for solving a problem logistically. I want people to recognize it.

Advantages of FTA

- Being able to organize and visualize the issues

- Being able to take steady problem-solving steps

- Being able to identify the problem

I have created FTA on several occasions. This is very useful for complex issues. However, my purpose in creating FTA was a little different.

It wasn't a method for solving problems, it was about introducing others to the idea of problem solving.

I can solve those problems myself, but I can't deal with it every time.

So I did this for the purpose of developing information to others by presentation of the problem and what to do about it.

It's the same objective as what I'm doing on this site.

RELATED) The need to properly understand the essence of problem and common misunderstandings

RELATED) Overview of 5-why Analysis at manufacturing site

RELATED) Problem Analysis Methods for Manufacturing Sites (Use of Histogram)